Carpenter Shorts

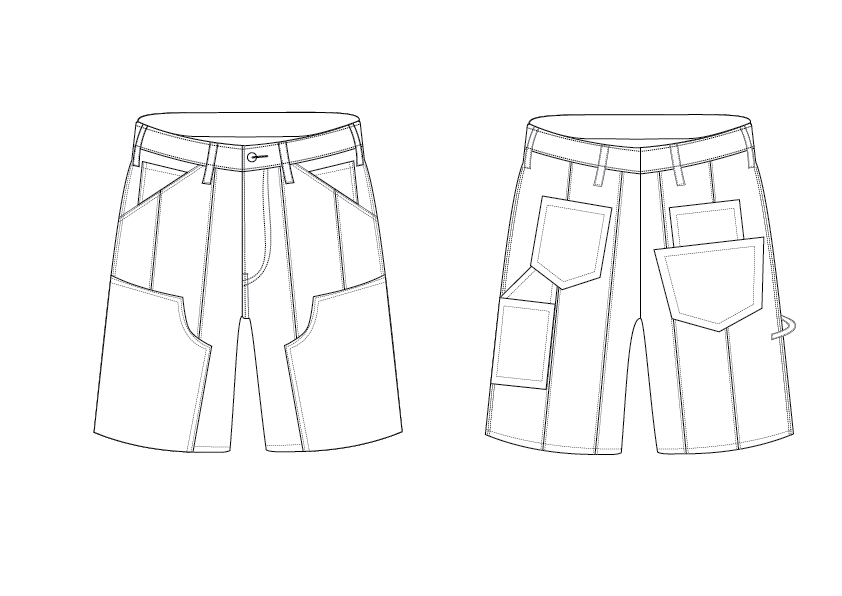

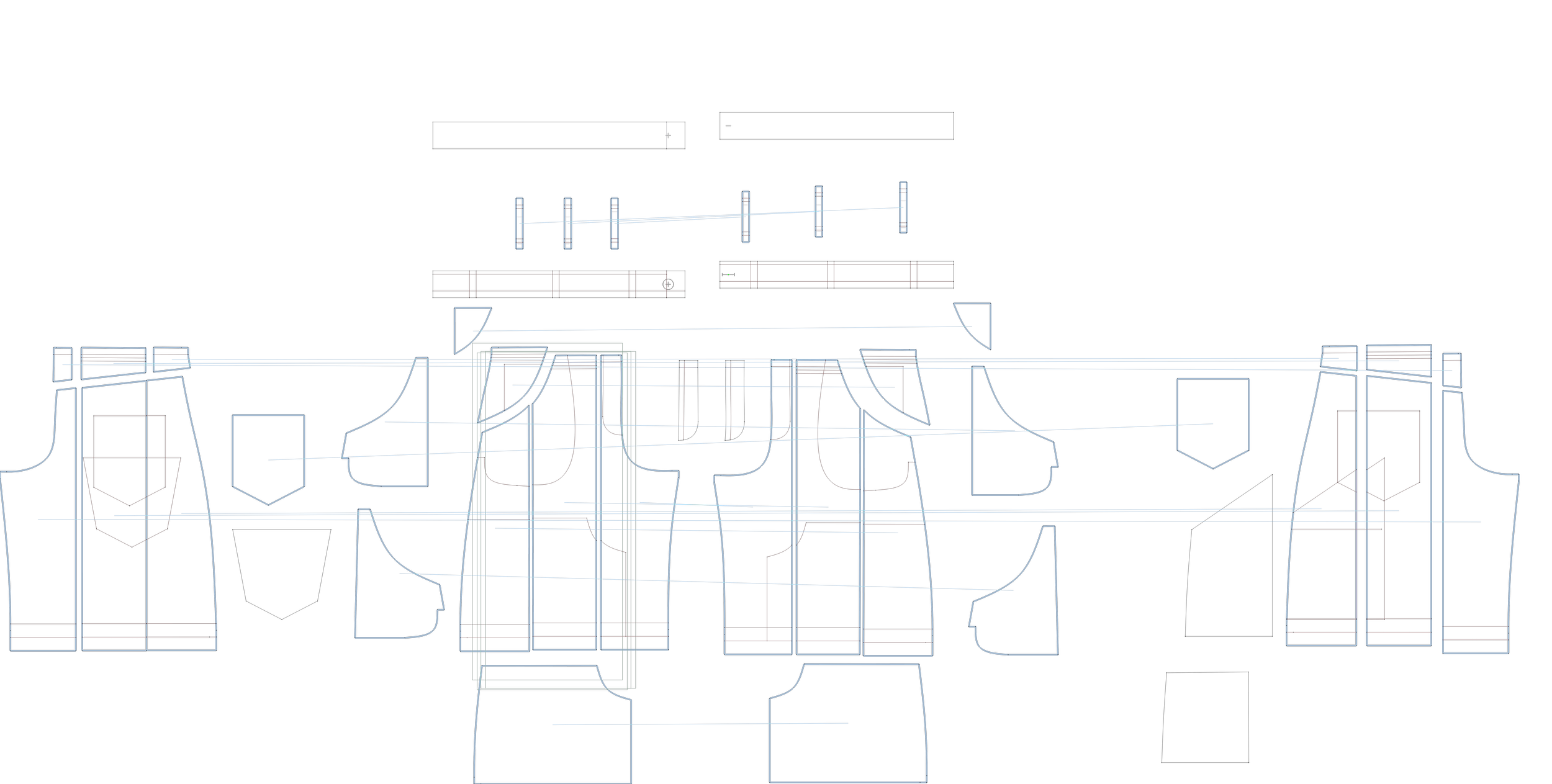

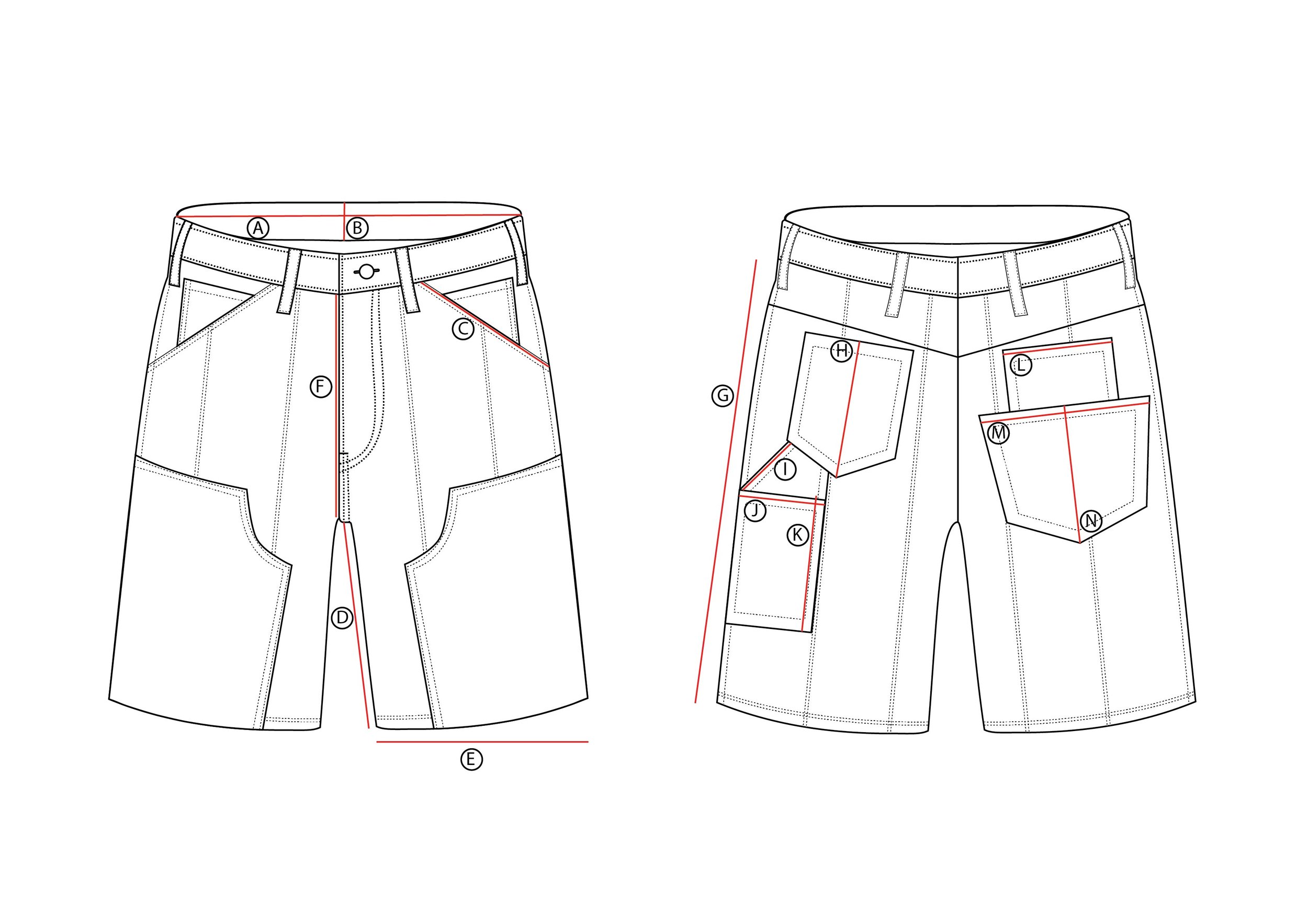

(Dec. 2025) This is a pair of carpenter jeans I designed inspired by a pair of regular Levi’s denim shorts that I own. I wanted to go away from the classic look of carpenter shorts and jeans, but not too far that you wouldn’t be able to recognize them without it being explained. With that in mind I feel like the changes to the design of the shorts wasn’t many, but they were significant. To start, I decided to split the front leg panels into three equal parts. I like the look of the added seam lines, especially after adding the topstitching to it. For the topstitching, I decided of making it two rows with one being red and one being white. I also made sure the stitching was thicker at 150 tex, and applied it to every seam as well as the edges of the pockets, the belt loops, the hem, and the panel sewn on the front leg. The back of the garment includes the double pocket on the right leg, the same pocket design that I had on the double waistband denim jeans. Still not sure if I like that pocket design because of how it looks, or if it’s because it’s unconventional. Next, I added a triangular and square, stacked pocket design that was from the reference pair of Levi’s shorts. Finally, I sewed the top edge of the leg patterns 1/2” in the waistband. This was also from the original reference pair, and I think it was done to create a more durable waistband.

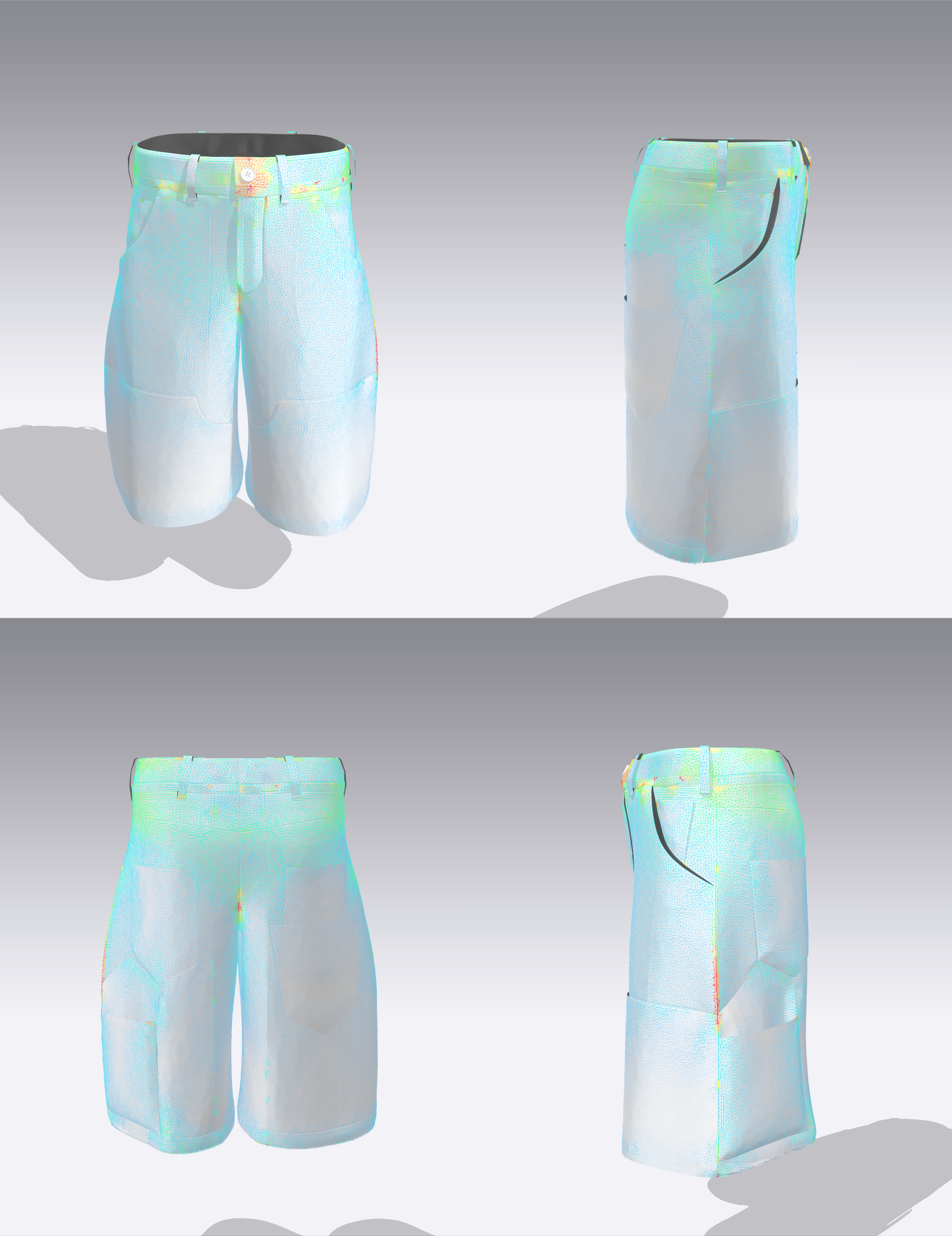

Overall, I am extremely pleased with this project. I got to learn and use the strain display function for the first time to help me make sure that the fit of the garment wasn’t to tight. While there is some strain where the button is, I believe this is because of the button being placed through the buttonhole. Something else I started to understand better was how order of operations works within Clo3D. Better understanding helped me to create a garment that didn’t have many defects, but I do think the order of operations could cause the bulkiness and excess strain on the button section because of how the fly and fly facing interacts with the front, innermost leg panel.

(1/9/26 Update): Contact was made with a manufacturer in China and production is set to begin within the next week with completion expected in mid to late March due to the holidays over there; this is something I will be mindful of in the future. While the design couldn’t be made to my exact liking due to certain design elements and factory limitations, I am still overall pleased with the design that will be made. Knowing factory capabilities, as well as just the overall feasibility of certain designs and their elements was something that I learned during the process and will be more conscious of with future designs. One of the most important things I learned during this process was the importance of communication, not just verbally but also in drawings. While the drawings accurately communicated most of my design intent, there were still some areas which me and the manufacturer had to discuss and come to an understanding on.